Project of Alanya Municipality is Industrialized

The Banana Project, which was initiated by Alanya Municipality in 2015, took a big step towards industrialization with the project of manure and animal feed

The equipment used in the manufacturing process of microbial fertilizers in BMusa was designed and built by engineers according to the latest technologies.

Hygiene and biological trust are at the forefront during production.

In the equipped microbiology laboratory, the first stages of production, process control and final quality control of the finished product are carried out by senior microbiology experts.

Liquid Fluid carrier used in microbial fertilizers (bacteria living area); It is a special formula that provides the best protection of bacteria until the use of fertilizer. The main component – the banana tree trunk juice, is produced from banana tree.

All these processes increase the efficiency, quality and long shelf life of fertilizers.

Our Working Principle: Hygiene, Control and Trust

Organic Acid Complex ANTİSALT

Naturally fermented pH reducer SALTEX

Organic fertilizers containing amino acids MULTI, MULTI PLUS

Microbial fertilizers containing live bacteria VITA, GREEN

NK, NPK'lı organomineral fertilizers ROOT, FERTİ, JET

Micro elements IRON FE EDTA, MIX, COMBI, CALCIUM, ZINC ZN, ZN8NK, NPK'lı liquid fertilizers FORTE, STIM, BLOOM

The Banana Project, which was initiated by Alanya Municipality in 2015, took a big step towards industrialization with the project of manure and animal feed

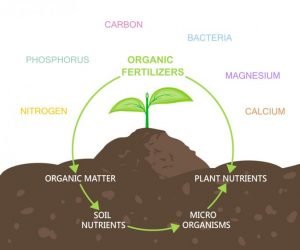

Reduce chemical fertilization by using microbial fertilizers in BMusa. Excessive use of nitrogen and phosphorous fertilizer increases the cost and causes environmental pollution.

BMusa bacteria contained microbial fertilizers produce auxin hormone and promote cell proliferation, cell division and alteration.

BMusa microbial fertilizers contain useful live bacteria, soil-borne harmful bacteria are suppressed.

BMusa microbial fertilizers convert the organic and inorganic phosphorous in the soil into the form of the plant.

Live bacteria, which decompose organic residues and waste in the soil and provide plant nutrition, have practically disappeared due to the use of chemical fertilizers

Opened in 2018 in Alanya, BAUMANN Banana Waste Recycling Plant is located on 17 acres of land and has a closed area of 1900 m2. The main aim of the plant is to evaluate the residual plant waste after the harvest of banana fruit and to bring it into the economy. Our plant produces vegetable origin solid and liquid organic and microbial fertilizers using as raw material banana tree stump and branches.

Capacity of the Plant: 2873 tons / year Solid Fertilizer, 7056 tons / year Liquid Fertilizer.

Total investment amount: 10 million TL / 2018